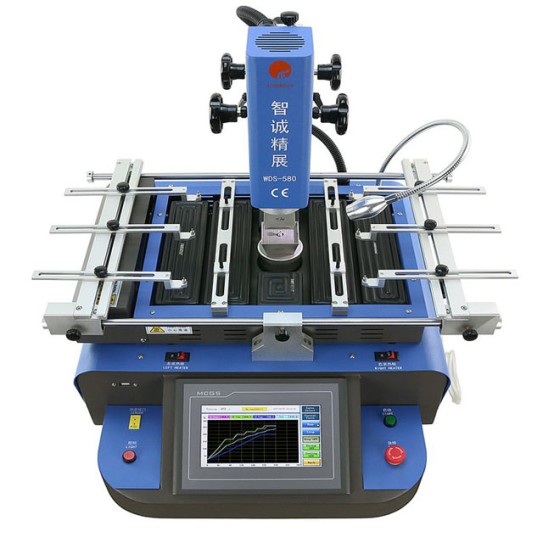

BGA Rework Station WDS-580

-

₹119,000.00

Terms & Conditions

- Pre-Order, Order in advance

- Delivery time 30 to 40 Days

- (40000 forty Thousand) payment in advance required at the time of placing the order remaining amount at the time of Dispatching.

Product Description

Manual BGA Rework Station

Model: WDS-580

Repair Success Rate:More Than 99%.

Using The Industrial Touch Screen.

Independent 3 Heating Zones, Hot Air Heating / Infrared Preheat. (temperature accuracy ± 3℃).

With CE Certification.

Parameter

1 | Power | AC 220V±10% 50Hz |

2 | Overall dimension | L500mm*W590mm*H650mm |

3 | PCB size | Max 400mm*370mm Min 10mm*10mm |

4 | BGA size | Max 60mm*60mm Min 1mm*1mm |

5 | PCB thickness | 0.3-5mm |

6 | Weight of machine | 40KG |

7 | Warranty | 1 year |

8 | Total power | 4800W |

9 | Payment way | T/T、Western Union |

10 | Usage | Repair chips / phone motherboard / Laptop Motherboard etc |

11 | Electrical material | Touch screen+Temperature control module+PLC control |

12 | Location way | V-shape card slot+Universal jigs |

Operation System

Manual mode.

Can solder, desolder, mount, pick and replace chip.

User-friendly.

Upper up/down moving knob.

Front/back moving knob.

Flexibility adjust the position of upper heater.

Instantly analyze temperature on touch screen, which effectively avoids failed repairing.

1. Can set different temperatures according to different types of BGA.

2. Multiple storage for temperature profiles for different PCB. Same PCB uses same profile.Time-saving.

Top heater (hot air 800w)

1.Reflow vent design ensure focused and even heating effectively increase.

2.Top hot air flow is adjustable, to meet the demand of any chip. 3.Top heater can be equipped with different size of nozzles for

different size of chips.

Bottom heater (hot air 1200w) 1.Height of bottom heater is adjustable. 2.Nozzles is different size available for different

chips.

Preheating plate (infrared 2700w)

1.Infrared heating is more easily absorbed by PCB.

2.Infrared heating zone can adjust the output power

according to the actual requirement.

Left heater control button Right heater control

They can precisely control the infrared heating zones

1.Distance between PCB and bottom nozzle can be adjusted with this rotary handle.

2.Suitable distance is 1-3mm.

Safety System

With CE certification.

With automatic power-off protection device when abnormal accident happens and double over-temp protection function.

Powerful cross cooling fan

Produce cross cool air flow as soon as soldering/desoldering process finish, which effectively avoid deformation of PCB.

Cool air flow will be from top and bottom nozzles as soon as soldering/desoldering process finish,high temperature will drop to normal temperature soon.

Led light

Can help you clearly see the melting condition of solder ball and check if there is any dirty on PCB and chip.

Preheating plate

Ensure that the PCB is evenly heated.

Power switch

Ensure 100% safety of operator and machine.

Voice warning

10 seconds before soldering/desoldering process complete.